Продукция

-

Вертикальный обрабатывающий центр MVL855S система Siemens

-

Высококачественный обрабатывающий центр VMC855

-

MVL1165 Большой обрабатывающий центр

-

Горизонтальный обрабатывающий центр DRC HME63

-

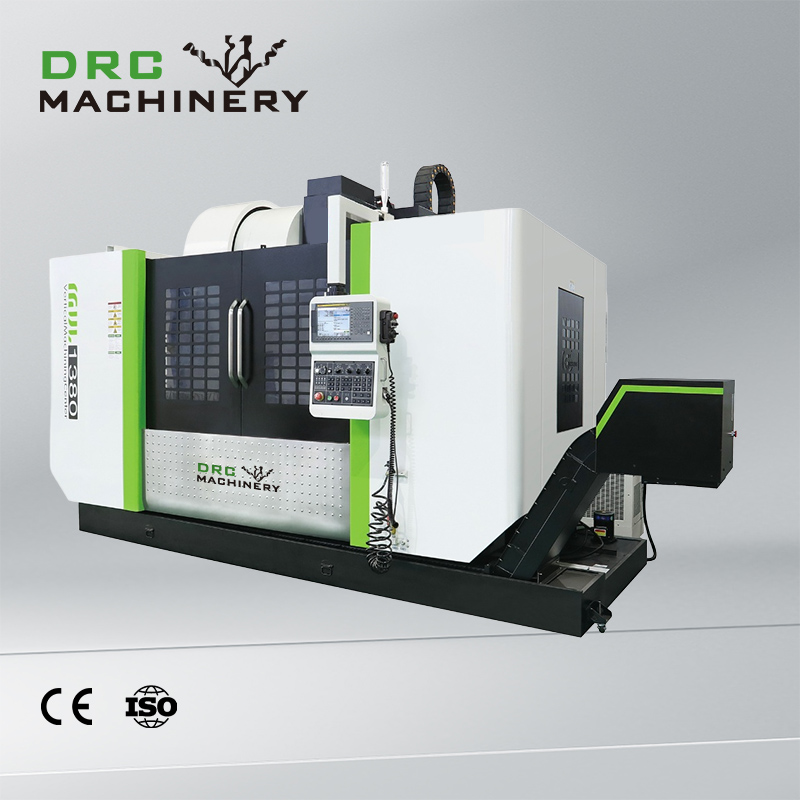

Вертикально-фрезерный обрабатывающий центр с ЧПУ MVL1380 с системой управления Fanuc

-

VM960 Алюминиевый профиль 3-осевой вертикальный автоматический сверлильно-фрезерный станок с ЧПУ

-

V11 высокая скорость CNC вертикальный фрезерный обрабатывающий центр заводская цена

-

Вертикально-фрезерный обрабатывающий центр с ЧПУ MVL1890 с системой управления Fanuc

-

Высококачественный обрабатывающий центр VMC1370

-

Efficient Ball valve Grinding Machine for Valve Industry

-

Немецкий малогабаритный токарный станок с ЧПУ HT2

-

GTD – 0310 – 03NA, диаметр 3 мм, диаметр стебля 6 мм, применяется для обработки стали, нержавеющей стали и чугуна

-

Портальный обрабатывающий центр GMF4019T

-

Высокоточный вертикальный обрабатывающий центр VMC1680 — идеальный выбор для вашего производства

-

GMF5030AR Портальный обрабатывающий центр

-

CK6150-1000 ЧПУ токарный станок – высокая производительность и гибкость в обработке

Вертикальный токарный станок C/CK5140

| Parameters | Unit | C/CK5240 |

| The Max. turning table diameter | mm | 4000 |

| The worktable diameter | mm | 3150 |

| The artifact max. height | mm | 1600/2000 |

| The largest workpiece weight | kg | 12000 |

| Right tool rest rest max. cutting force | kg | 3500 |

| Left head rest max. cutting force | kg | 3000 |

| The max. cutting force | kg | 6300 |

| The worktable max. torque | kg/h | 6300 |

| The worktable variable series | Two gear stepless | |

| Table speed range | r/min | 2-50 |

| Feeding series | stepless | |

| Feed range | mm/min | 0.25-90 |

| Beam tip | mm | 1250/1650 |

| Head horizontal travel | mm | 2170 |

| Vertical travel tool rest | mm | 1000 |

| Beam movement speed | mm/min | 350 |

| Rest fast moving speed | mm/min | 1560 |

| Rest the max. turning Angle | ° | ±30 |

| Tool party size (width x height) | mm | 40×50 |

| Main motor power | kw | 55 |

| Machine tool appearance size(LxWxH) | mm | 6680×5010×5080 |

| Machine weight | kg | 43600 |

| Configuration | Brand | Note |

| Crossbeam lifting screw | Shandong Jining Lead Screw Factory | T type |

| X/Z axis CNC tool holder | Taiwan Dinghan | High precision ball type |

| gear | Shenyang Machine Tool Co., Ltd. Gear Branch | The material, gear grinding process and hardness of the gears reach level 6 accuracy. |

| Bearing | Small bearings:Luoyang Bearings Main bearings:Wafangdian Bearings |

The precision and hardness reach P5 level, and the main bearing models are 3182156 and 3182140. |

| Cnc system | GSK980TDI | |

| Hydraulic system | Domestic | |

| Worktable guide rail | Domestic | Zinc-aluminum alloy material, small thermal deformation, wear resistance high. |

| Electrical appliances | Chint/Delixi | |

| Planetary reducer | Taiwan Seiko | |

| Guide rail protective cover/drag chain | Domestic | |

| Main motor | Domestic | |

| CNC precision coupling | Domestic | |

| Castings | Domestic | HT250 |

Описание

маркер

General form:

The machine is mainly composed of workbench, workbench base, column, beam and vertical tool rack. The main parts of this machine are made of HT250 cast iron using resin sand technology and aging treatment (artificial aging and vibration aging) after roughing. Casting quality is reliable, without cracks, pores and shrinkage holes. After aging treatment, the casting has a stable structure, which ensures the stability of the machine during use. The product quality certificate contains a report on the analysis of the chemical composition, a report on the heat treatment and time curve of heat treatment temperature.