Продукция

-

GMF2213T Портальный обрабатывающий центр

-

Твердосплавный фрез с плоским концом, диаметр 12 мм

-

GMB4030LX Пятиосевой мостовой обрабатывающий центр с портальной конструкцией

-

твердосплавные сверла с внешним охлаждением диаметром 6.5 мм

-

Токарный станок с ЧПУ HT5: высокоточный, мощный и многофункциональный выбор для профессиональной металлообработки

-

Вертикальный токарный станок C/CK5110

-

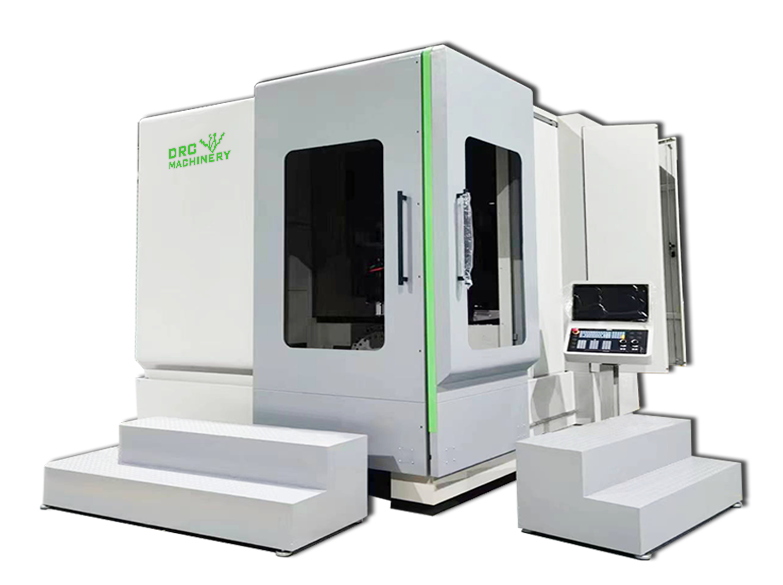

Вертикальный обрабатывающий центр DRC MVL855S: Высокоточный ЧПУ-оборудование для металлообработки в России

-

BT50 Вертикальный Обрабатывающий Центр MVL1165S Система Siemens

-

Высокоточный швейцарский токарный станок RC206

-

Расточно-фрезерный обрабатывающий центр с ЧПУ DBM130B

-

Горизонтальный обрабатывающий центр DRC DHM80

-

Токарный станок с ЧПУ и наклонной станиной TCK36A

-

VMC1680 Большой обрабатывающий центр

-

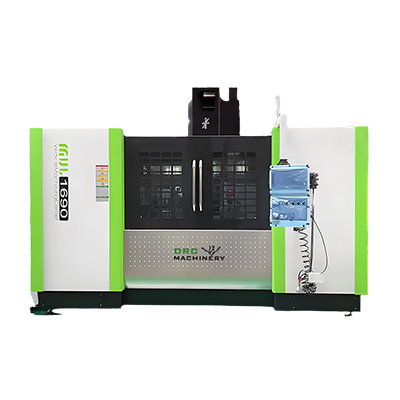

MVL1690 Высокоточный вертикальный обрабатывающий центр Фрезерный станок с ЧПУ Обрабатывающий центр

-

Efficient Ball valve Grinding Machine for Valve Industry

-

Станок для сверления глубоких отверстий

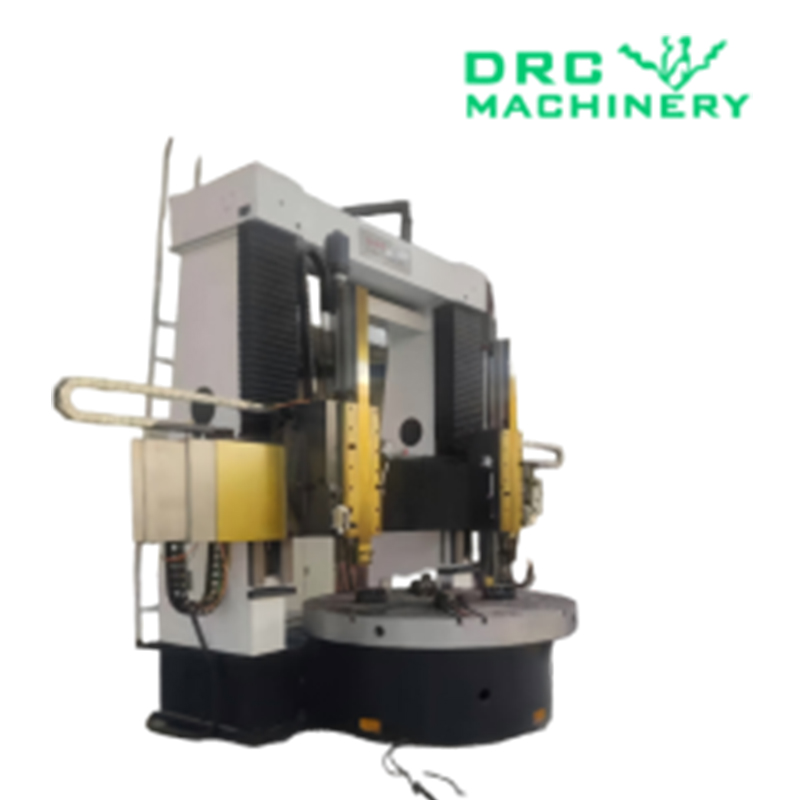

Вертикальный токарный станок C/CK5120

C/CK5120 в основном состоит из верстака, основания верстака, колонны, поперечной балки и вертикального подручника. Основные части этого станка изготовлены из чугуна HT250 с использованием технологии смоляного песка и состарены после грубой обработки (искусственное старение и вибрационное старение). Качество литья надежное и не имеет трещин, пор, усадочных раковин или белой литой структуры. Отливка имеет стабильную структуру после вибрационной обработки старением, что обеспечивает стабильность станка во время использования. Сертификат качества продукции содержит отчет об анализе химического состава расплавленного чугуна, отчет о термической обработке и кривую зависимости температуры от времени термической обработки.

Описание

маркер

C/CK5120 Технические параметры:

| № | Параметры | Единица | C/CK5120 |

| 1 | Максимальный диаметр обработки вертикального держателя инструмента | мм | 2000 |

| 2 | Диаметр стола | мм | 1800 |

| 3 | Максимальная высота заготовки | мм | 1000 |

| 4 | Максимальный вес заготовки | Тонн | 5 |

| 5 | Диапазон скоростей стола | об/мин | 15-100 |

| 6 | Серия скоростей стола | Бесступенчатый | |

| 7 | Диапазон подачи держателя инструмента | мм/мин | 0,8-86 |

| 8 | Уровень подачи держателя инструмента | Бесступенчатый | |

| 9 | Максимальная сила резания вертикального держателя инструмента | кг | 1200 |

| 10 | Общая сила резания | кг | 2000 |

| 11 | Максимальный крутящий момент | кг/м | 1250 |

| 12 | Уровень перемещения вертикального упора ножа | мм | 1115 |

| 13 | вертикальный | мм | 750 |

| 14 | Перемещение балки | мм | 1000 |

| 15 | Скорость быстрой перемещения балки вертикального упора инструмента | м/мин | 1,8 |

| 16 | Скорость подъема балки | м/мин | 0,44 |

| 17 | Размер сечения держателя инструмента (ширина × высота) | мм | 30×40 |

| 18 | Мощность главного двигателя | кВт | 30 |

| 19 | Крутящий момент серводвигателя | НМ | 15 |

| 20 | Габариты станка (длина × ширина × высота) | мм | 3100*3000*3450 |

| 21 | Вес станка (прибл.) | Т | 16 |

C/CK5120 Стандартная конфигурация:

1. Балка поднимается и опускается с помощью Т-образного винта (Shandong Jining Screw Factory).

2. Зубчатая передача станка: Материал, технология и твердость зубчатой передачи (Shenyang Machine Tool Co., Ltd. Gear Branch) используются для достижения точности 6-го уровня.

3. Подшипники станка: малые подшипники в основном из Лояна, а главные подшипники вала изготавливаются из (Wafangdian Bearing Factory) с точностью и твердостью, достигающей уровня P5.

4. Гидравлическая система станка: гидравлические детали Changzhou Jinpeng.

5. Направляющая верстака: изготовлена из цинково-алюминиевого сплава, произведенного в Уху, провинция Аньхой, с малой тепловой деформацией и высокой износостойкостью.

6. Электроприборы станка: используются известные отечественные производители. (В основном Tianzheng и Delixi)

7. Крупные детали станка: HT250 (собственного производства)

C/CK5120 Принадлежности, поставляемые вместе с машиной:

| № | Имя | Примечание | КОЛ-ВО |

| 1 | Колонна стойки | 1 | |

| 2 | Редуктор | 1 | |

| 3 | Рабочий стол | 1 | |

| 4 | Коробка подачи | 2 | |

| 5 | Балка | 1 | |

| 6 | Вертикальный подручник | 2 | |

| 7 | Механизм подъема балки | 1 | |

| 8 | Гидравлический привод управления | 1 | |

| 9 | Главный двигатель | 1 | |

| 10 | Кнопочная станция подвески | 1 | |

| 11 | Кулачковый патрон | 4 | |

| 12 | Технические документы | ||

| 13 | Руководство по эксплуатации | 1 | |

| 14 | Сертификат соответствия | 1 | |

| 15 | Упаковочный лист | 1 | |

| 16 | Набор инструментов | 2 | |

| 17 | Болт фундаментный | М24Х500 | 14 |

| 18 | Ключ патронный | 24; QIS92--3 | 1 |

| 19 | Квадратный торцевой ключ | 22; QIS92--8 | 1 |

| 20 | Регулировка упорного железа | 240 мм | 14 |

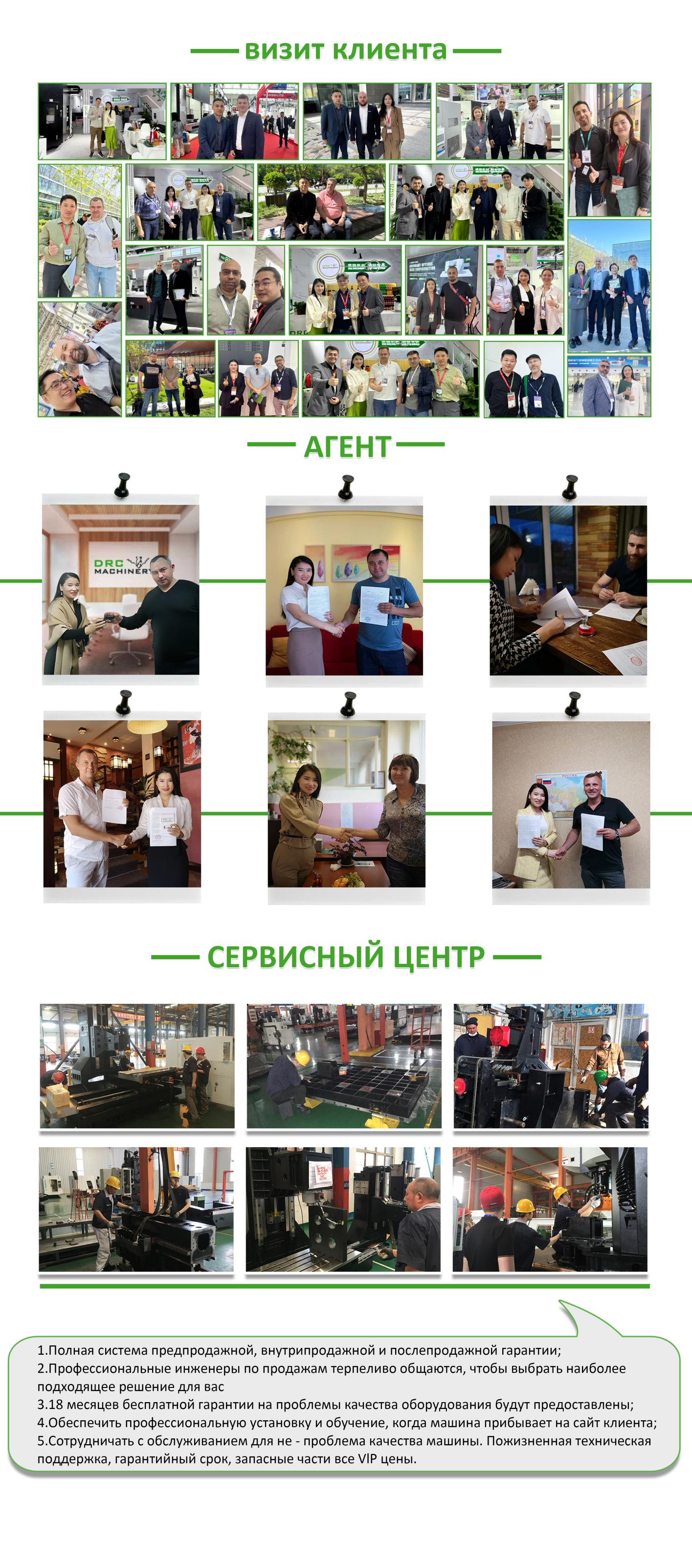

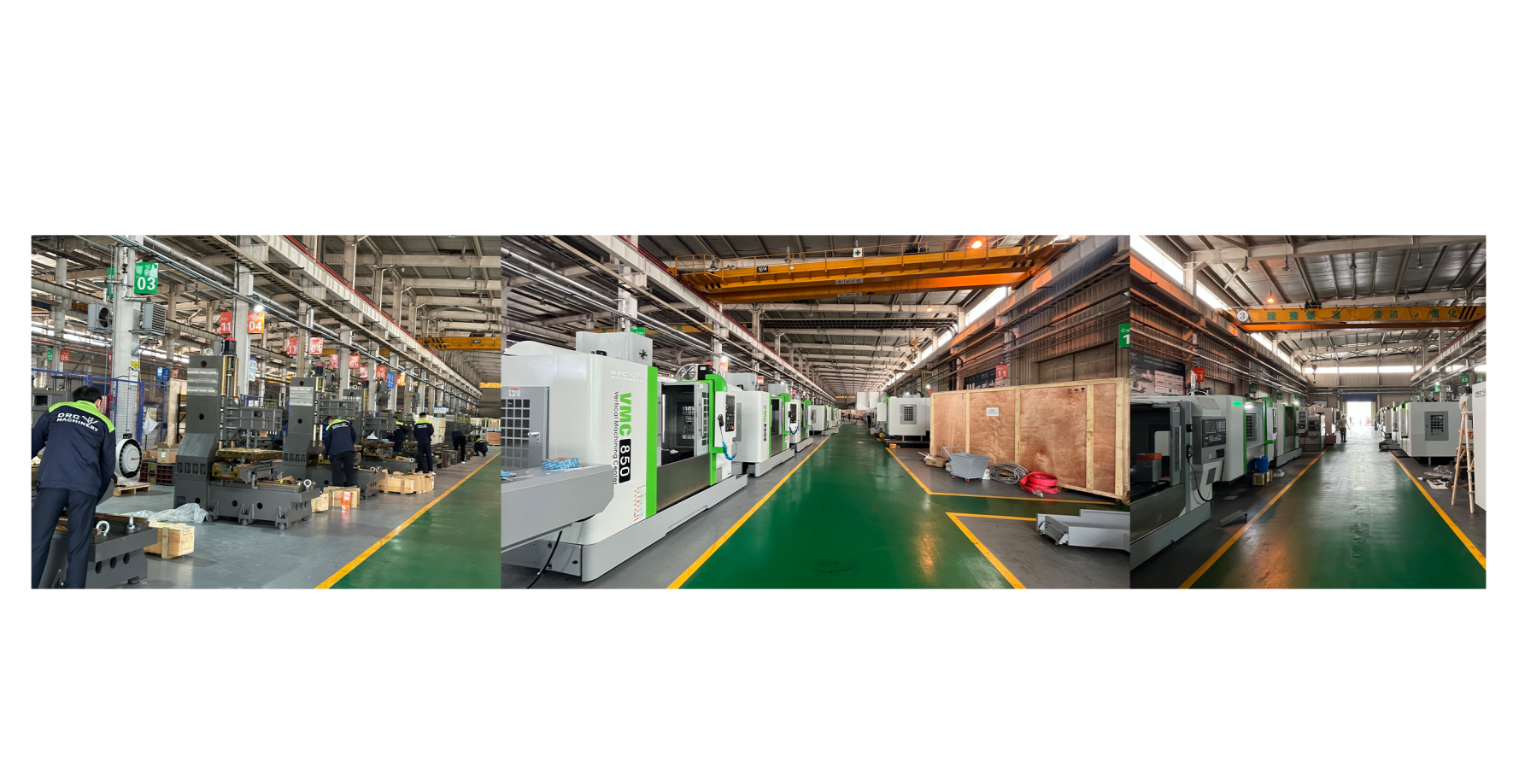

О компании

Гарантия качества / Всемирное признание / Высокие технологии

DRC machinery— это компания, которая неизменно посвящает свою деятельность области металлообработки. Мы специализируемся на проектировании, разработке, производстве, продаже и послепродажном обслуживании высококачественных китайских станков. Следуя пути интеграции производства и торговли, мы чувствуем пульс времени, постоянно внедряем инновации и предоставляем клиентам по всему миру продукцию и услуги первоклассного качества.

Гарантия качества

Продукция DRC Machinery экспортируется в более чем 180 стран и регионов по всему миру

и установила сотрудничество с более чем 2500

клиентов. DRC Machinery предоставляет клиентам комплексные

услуги и универсальные решения.

На протяжении многих лет компания DRC machinery постоянно расширяет линейку продукции и строго производит современное ЧПУ-оборудование различных моделей в соответствии со стандартом CE. Ассортимент продукции включает: токарные станки с ЧПУ, обрабатывающие центры с ЧПУ, портальные обрабатывающие центры с ЧПУ, горизонтальные обрабатывающие центры, пятиосевые обрабатывающие центры, токарно-фрезерные комбинированные станки, вертикальные токарные станки, прецизионные автоматические токарные станки (с подачей прутка), трубонарезные токарные станки и другие специализированные токарные станки. Компания сертифицирована по системе менеджмента качества ISO 9001 и имеет более 10 национальных патентов.

Всемирное признание

Продукция DRC Machinery экспортируется в более чем 180 стран и регионов по всему миру

и установила сотрудничество с более чем 2500

клиентов. DRC Machinery предоставляет клиентам комплексные

услуги и универсальные решения.