Продукция

-

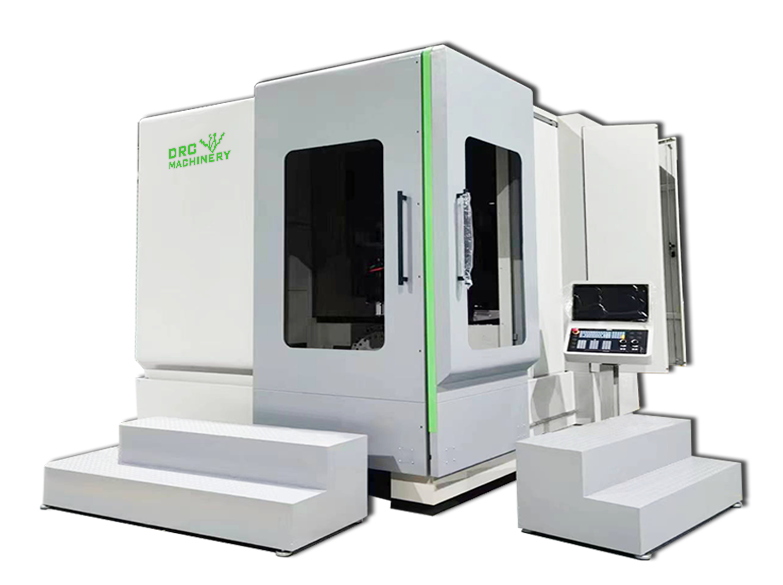

Вертикальный обрабатывающий центр MVL855S система Siemens

-

DHM63 горизонтальный обрабатывающий центр двойной рабочий стол фрезерная машина с чпу на

-

Токарный станок с ЧПУ с наклонной станиной TCK46A

-

Вертикально-фрезерный обрабатывающий центр GVL1000

-

Малый обрабатывающий центр с ЧПУ VMC640

-

Efficient Ball valve Grinding Machine for Valve Industry

-

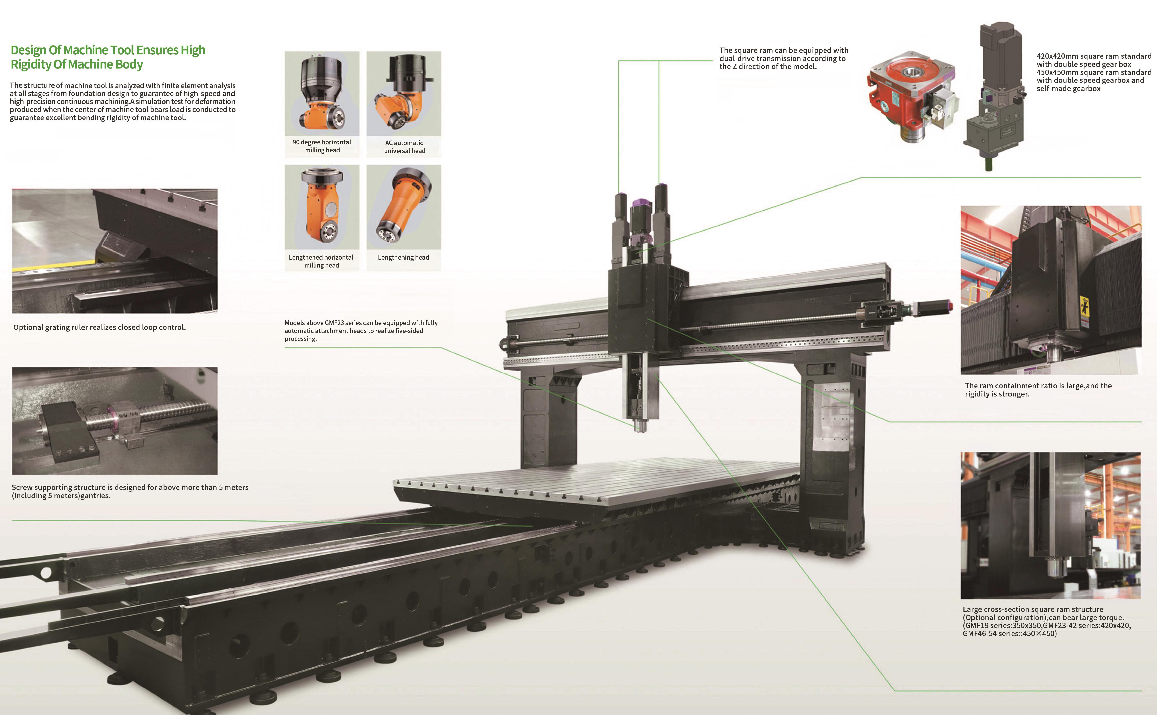

Пятиосевой мостовой портальный обрабатывающий центр GMB2520LX

-

VMC1055 обрабатывающий центр

-

MVL1165 Большой обрабатывающий центр

-

VMC1680 Большой обрабатывающий центр

-

DHM50 Горизонтальный обрабатывающий центр

-

Токарный станок с чпу высокого качества TCK36A

-

VT1200 Вертикальный токарный центр

-

China factory Big Spindle Bore Cnc Pipe Thread Lathe Qk1319 Pipe Threading Machine

-

CK6150-1000 ЧПУ токарный станок – высокая производительность и гибкость в обработке

-

Токарный станок с ЧПУ TCK50A

Токарный станок с ЧПУ с наклонной станиной TCK56A

| Parameter | Unit | TCK56A-500 | Note | |

| Max. rotation diameter on the bed | mm | Φ560 | ||

| Max. cutting length | mm | 560 | ||

| Max. cutting diameter | mm | Plate Type: Φ420

Bar Type: Φ340 |

||

| Max. rotation diameter on the slide | mm | Φ340 | ||

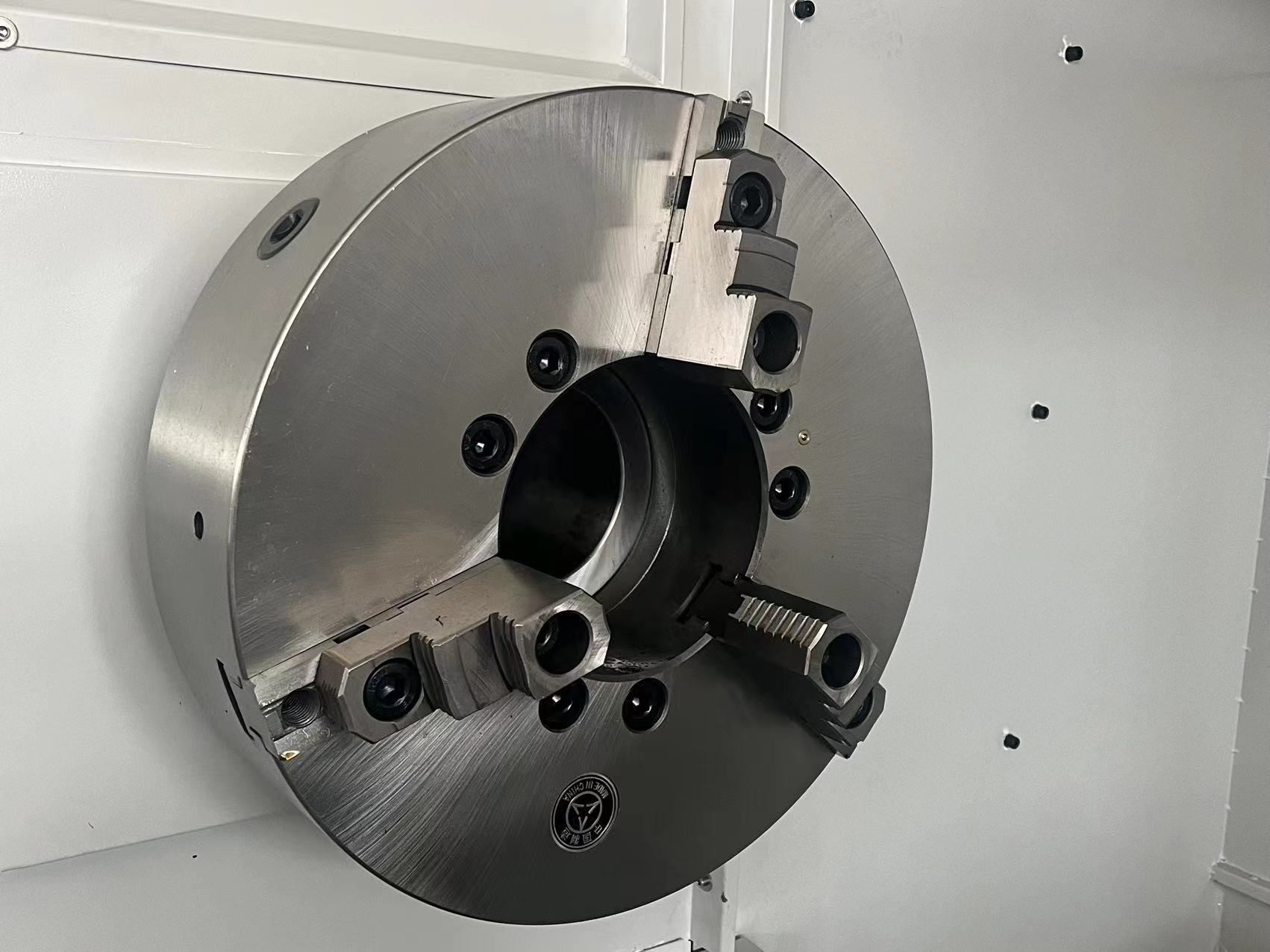

| Spindle end type and code | A2-6 | |||

| Spindle hole diameter | mm | Φ65 | ||

| Max. bar diameter | mm | Φ50 | Hollow chuck available | |

| Single spindle headstock | Spindle speed range /

spindle Max. output torque |

r/min/Nm | 50~3000 | GSK 988TA |

| Main motor output power | 30 minutes/continuous | kW | 15/11 | ZJY265A-11AM-B5 |

| Standard chuck | Chuck diameter | inch | 10 ² | |

| X-axis fast moving speed | m/min | 30 | Rolling guide rails | |

| Z-axis fast moving speed | m/min | 30 | Rolling guide rails | |

| X-axis travel | mm | 220 | ||

| Z-axis travel | mm | 560 | ||

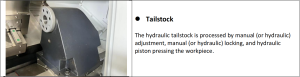

| Tailstock travel | mm | 450 | Cylinder drive rail | |

| Tailstock spindle taper | Mohs | 5# | ||

| Standard tool holder form | Horizontal 8-station | |||

| Tool size | External boring tool | mm | 25×25 | |

| Diameter of boring bar | mm | Ф40/Ф32 | ||

| Can choose the tool nearby? | Yes | |||

| Machine weight | Total weight | kg | 4000 | |

| Max. load | Plate type parts | kg | 200

(including chuck and other machine tool accessories) |

|

| Axle type parts | kg | 500

(including chuck and other machine tool accessories) |

||

| Machine tool appearance | Length × Width × Height | mm | 2850X2068X2200 | Without chip conveyor |

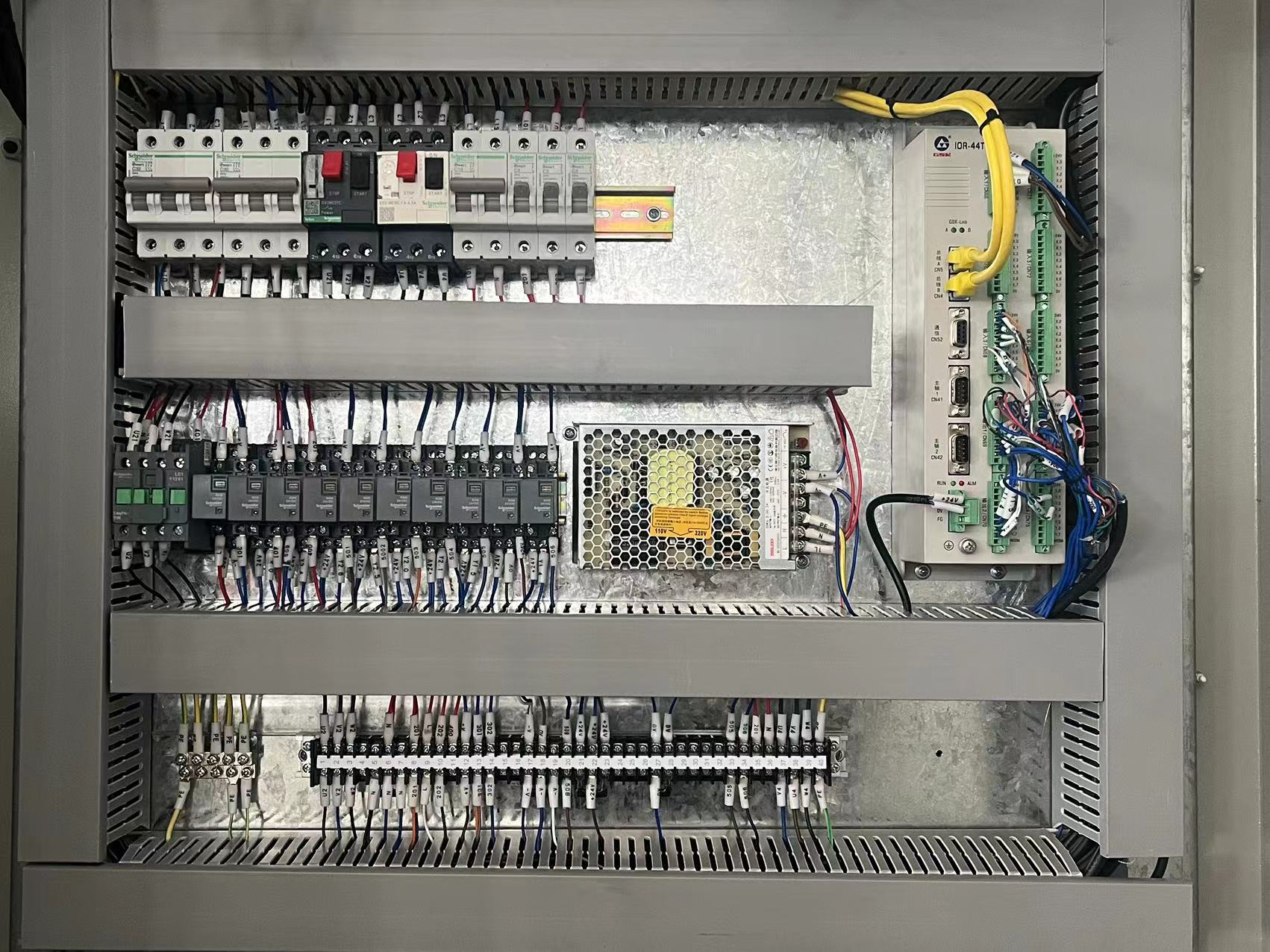

| Configuration | Specification | Brand |

| Controller | GSK988TA | GSK |

| Main motor | ZJY265A-11AM-B5 | GSK |

| X-axis motor | 130SJT-MZ100D | GSK |

| Z-axis motor | 130SJT-M100D | GSK |

| Spindle bearing | Front:NN3020K | Domestic |

| Middle:HTA020UADB(30°) | ||

| Back:NN3018K | ||

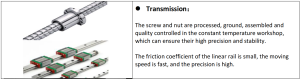

| X-axis ball screw | φ32×12-635 | Taiwan Hiwin |

| Z-axis ball screw | φ32×12-1042 | Taiwan Hiwin |

| X-axis linear guide | 35mm | Taiwan Hiwin |

| Z-axis linear guide | 35mm | Taiwan Hiwin |

| Tailstock guide | 35mm | Taiwan Hiwin |

| X-axis bearing | 25X62X15 | Japan NACHI |

| Z-axis bearing | 25X62X15 | Japan NACHI |

| Tailstock | Integral hydraulic tailstock | Domestic |

| Tailstock taper | MT5 | Domestic |

| Hydraulic chuck | 10” hollow | Domestic |

| Tool rest | Horizontal 8-station | Taiwan |

| Coolant system | 450W | Domestic |

| Accessory name | Specification | Qty. |

| Footing iron | 1 set | |

| Turning tool holder | External circular tool pressing block 25X25 | 1 set |

| End tool holder 25X25 | 2 pcs | |

| Boring tool holder φ32 | 1 pcs | |

| Boring tool holder φ40 | 1 pcs | |

| Chip cooling box | 1 set |

| Test Items | Acceptance Criteria | |

| Precision | IT6 | |

| Processing workpiece roundness | 0.0025mm/φ75 | |

| Machining workpiece cylindricity | 0.010mm / 150mm | |

| Machining workpiece flatness | 0.010mm/φ200mm | |

| Surface roughness of machined workpiece | Ra1.25μm | |

| Positioning accuracy | X-axis | 0.008 mm |

| Z axis | 0.01 mm | |

| Repeatability | X-axis | 0.004 mm |

| Z axis | 0.005 mm | |

Описание

маркер