Продукция

-

Горизонтальный обрабатывающий центр DHM50

-

MVL1165 Большой обрабатывающий центр

-

GMB3020LX Пятиосевой мостовой обрабатывающий центр с портальной конструкцией

-

Портальный обрабатывающий центр GMF2716

-

Высокоточный швейцарский токарный станок RC385

-

Вертикальный токарный станок C/CK518

-

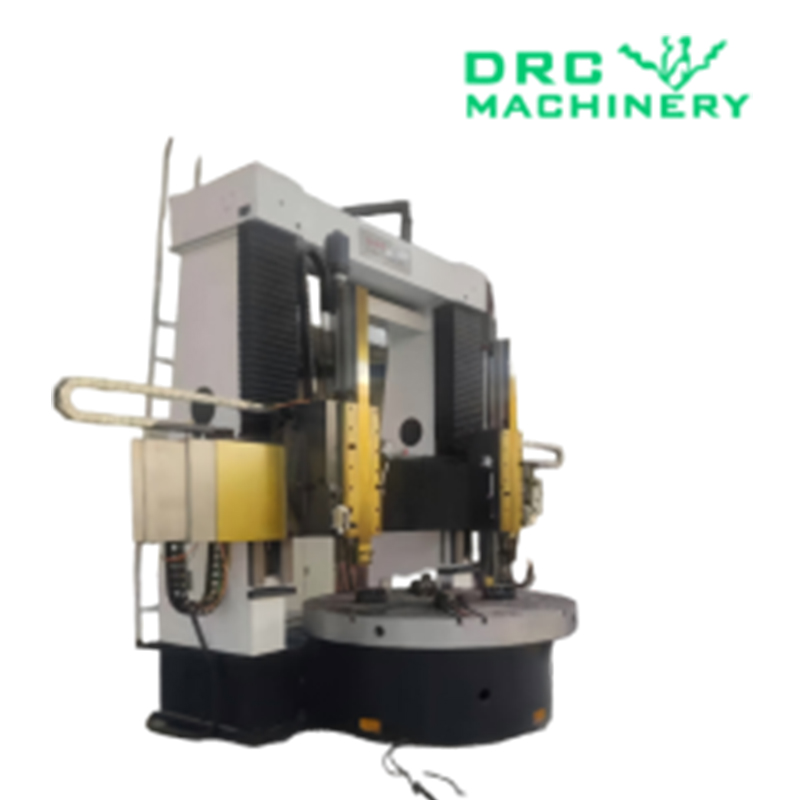

Вертикальный токарный станок C/CK5231

-

Вертикальный токарный станок C/CK5112

-

Вертикальный токарный станок VT800

-

Твёрдосплавное сверло диаметра 5.4 мм для Универсальной обработки.

-

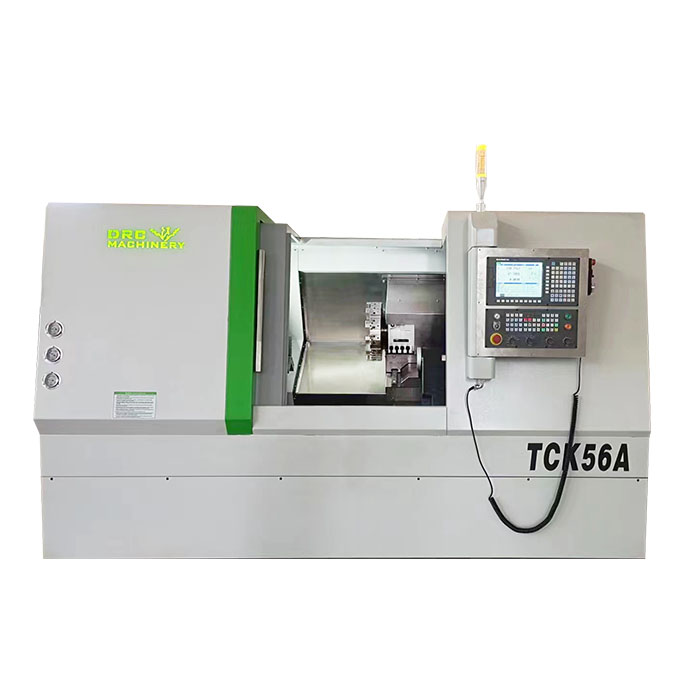

Токарный станок с ЧПУ и наклонной станиной TCK56A

-

GMF3015B Портальный обрабатывающий центр

-

Вертикальный обрабатывающий центр MVL1270E

-

твердосплавные сверла с внешним охлаждением диаметром 6.7 мм

-

Токарный станок с ЧПУ HT5: высокоточный, мощный и многофункциональный выбор для профессиональной металлообработки

-

Токарный станок с ЧПУ CK6150-2000mm: Надежность и производительность в каждой детали

Вертикальный токарный станок C/CK5116

C/CK5116 в основном состоит из рабочего стола, основания рабочего стола, колонны, балки и вертикальной инструментальной стойки. Основные части этой машины изготовлены из чугуна HT250 с использованием технологии смоляного песка и старения (искусственное старение и вибрационное старение) после черновой обработки. Качество литья надежное, без трещин, пор и усадочных раковин. После старения отливка имеет стабильную структуру, что обеспечивает устойчивость машины во время использования. Сертификат качества продукции содержит отчет об анализе химического состава, отчет о термической обработке и временную кривую температуры термической обработки.

Описание

маркер

C/CK5116 Технические параметры:

| № | Параметры | Единица | C/CK5116 |

| 1 | Наибольший диаметр вертикального подсвечника | мм | 1600 |

| 2 | Наибольший диаметр обработки головки ползуна | мм | 1400 |

| 3 | Диаметр верстака | мм | 1400 |

| 4 | Максимальная высота артефакта | мм | 1200 |

| 5 | Наибольший вес заготовки | тонна | 5 |

| 6 | Диапазон скоростей стола | об/мин | 5-160 |

| 7 | Серия | 16/бесступенчато | |

| 8 | Диапазон подачи головки ползуна | кг | 0,8-86 |

| 9 | серия | 12/бесступенчато | |

| 10 | Вертикальный подсвечник, макс. сила резания | кг | 2500 |

| 11 | Максимальная сила резания головки ползуна | кг | 2000 |

| 12 | Общая сила резания | кг | 4000 |

| 13 | Макс. крутящий момент | кг/м | 2500 |

| 14 | График вертикального подсвечника | мм | 916 |

| 15 | Вертикальный | мм | 800 |

| 16 | Опускание головки ползуна | мм | 630 |

| 17 | вертикальный | мм | 900 |

| 18 | Опускание балки | мм/мин | 650 |

| 19 | Скорость быстрой подачи головки ползуна | мм/мин | 1,8 |

| 20 | Скорость подъема балки | мм | 0,44 |

| 21 | Размер поперечного сечения стержня инструмента (ширина x высота) | кВт | 30x40 |

| 22 | Мощность главного двигателя | мм | 30 |

| 23 | Размер внешнего вида станка (Д x Ш x В) | кг | 2600x2665x3528 |

| 24 | Вес станка | мм | 12500 |

C/CK5116 Стандартная конфигурация:

① Балка поднимается и опускается с помощью Т-образного винта (Shandong Jining Screw Factory).

②Зубчатая передача станка: Материал, технология и твердость зубчатой передачи (Shenyang Machine Tool Co., Ltd. Gear Branch) используются для достижения точности 6-го уровня.

③Подшипники станка: малые подшипники в основном изготавливаются из подшипников Luoyang, а главные подшипники вала изготавливаются из (Wafangdian Bearing Factory) с точностью и твердостью, достигающей уровня P5.

④ Гидравлическая система станка: гидравлические детали Changzhou Jinpeng.

⑤Направляющая верстака: изготовлена из цинково-алюминиевого сплава, произведенного в Уху, провинция Аньхой, с малой тепловой деформацией и высокой износостойкостью.

⑥Электроприборы станка: используются известные отечественные производители. (В основном Tianzheng и Delixi)

⑦Крупные детали станка: HT250 (собственного производства)

C/CK5116 Принадлежности, поставляемые вместе с машиной:

| № | Имя | Примечание | КОЛ-ВО |

| 1 | Колонна стойки | 1 | |

| 2 | Редуктор | 1 | |

| 3 | Рабочий стол | 1 | |

| 4 | Коробка подачи | 2 | |

| 5 | Балка | 1 | |

| 6 | Вертикальный подручник | 2 | |

| 7 | Механизм подъема балки | 1 | |

| 8 | Гидравлический привод управления | 1 | |

| 9 | Главный двигатель | 1 | |

| 10 | Кнопочная станция подвески | 1 | |

| 11 | Кулачковый патрон | 4 | |

| 12 | Технические документы | ||

| 13 | Руководство по эксплуатации | 1 | |

| 14 | Сертификат соответствия | 1 | |

| 15 | Упаковочный лист | 1 | |

| 16 | Набор инструментов | 2 | |

| 17 | Болт фундаментный | М24Х500 | 14 |

| 18 | Ключ патронный | 24; QIS92--3 | 1 |

| 19 | Квадратный торцевой ключ | 22; QIS92--8 | 1 |

| 20 | Регулировка упорного железа | 240 мм | 14 |

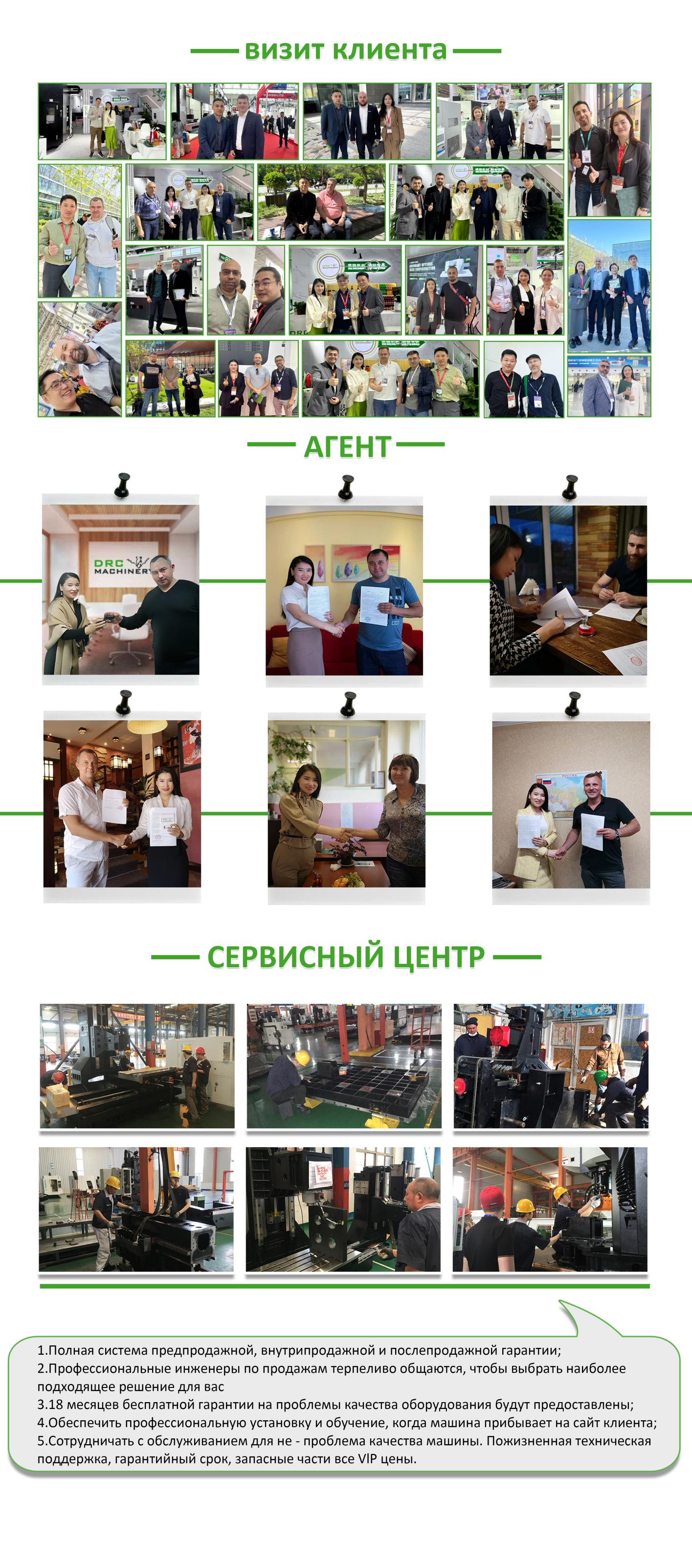

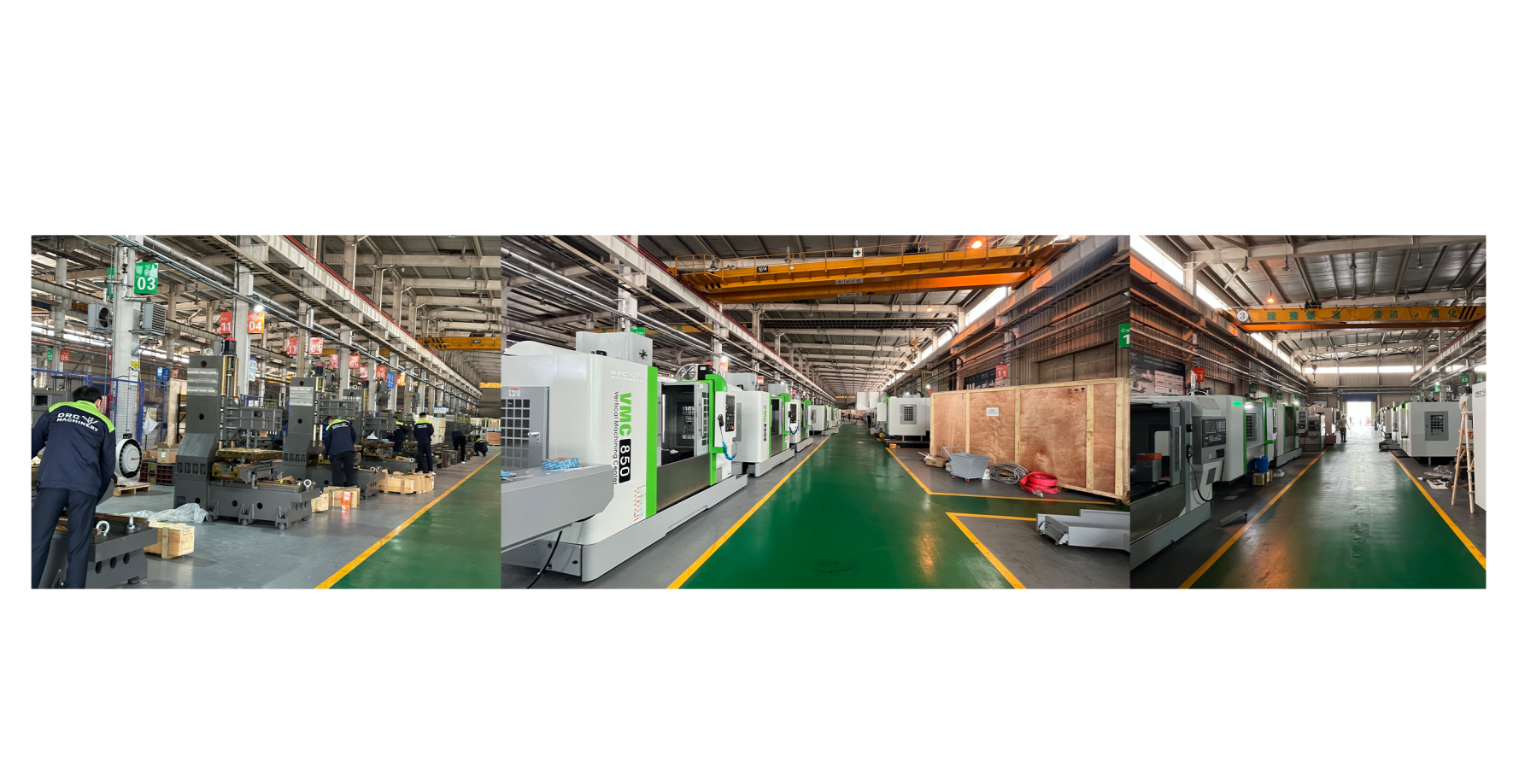

О компании

Гарантия качества / Всемирное признание / Высокие технологии

На протяжении многих лет компания DRC machinery постоянно расширяет линейку продукции и строго производит современное ЧПУ-оборудование различных моделей в соответствии со стандартом CE. Ассортимент продукции включает: токарные станки с ЧПУ, обрабатывающие центры с ЧПУ, портальные обрабатывающие центры с ЧПУ, горизонтальные обрабатывающие центры, пятиосевые обрабатывающие центры, токарно-фрезерные комбинированные станки, вертикальные токарные станки, прецизионные автоматические токарные станки (с подачей прутка), трубонарезные токарные станки и другие специализированные токарные станки. Компания сертифицирована по системе менеджмента качества ISO 9001 и имеет более 10 национальных патентов.

Всемирное признание

На протяжении многих лет компания DRC machinery постоянно расширяет линейку продукции и строго производит современное ЧПУ-оборудование различных моделей в соответствии со стандартом CE. Ассортимент продукции включает: токарные станки с ЧПУ, обрабатывающие центры с ЧПУ, портальные обрабатывающие центры с ЧПУ, горизонтальные обрабатывающие центры, пятиосевые обрабатывающие центры, токарно-фрезерные комбинированные станки, вертикальные токарные станки, прецизионные автоматические токарные станки (с подачей прутка), трубонарезные токарные станки и другие специализированные токарные станки. Компания сертифицирована по системе менеджмента качества ISO 9001 и имеет более 10 национальных патентов.

Всемирное признание

Продукция DRC Machinery экспортируется в более чем 180 стран и регионов по всему миру

и установила сотрудничество с более чем 2500

клиентов. DRC Machinery предоставляет клиентам комплексные

услуги и универсальные решения.